The outbreak of pandemic has instigated a sudden uncertainty in the supply chain management, stimulating industries to enhance the automation of operations for maximizing productivity. Industries encounter many challenges while managing global supply chains, operations, technologies and numerous traders. These challenges include limited details on the product location in a supply chain, delayed updates of product’s physical movement, indefinite end to end reporting, etc. There is an urgency to eradicate these barriers from the supply chain of industries to make trading more accessible, programmable and searchable and to mitigate the risks of losing revenue or customers. OCR technology implementation is yet the supply chain game changer.

Can supply chain operations be simplified by just clicking a picture? On that account, Optical Character Recognition (OCR) is basically an automated technology that collects real-time data and identifies it, setting off as an integral part of many contemporary industries. Many industries, like container shipping, use this technology to automate the identification and accessibility of its equipment and products throughout the supply chain.

OCR captures a series of numbers or distinctive patterns from a container using electronic imaging devices. The extracted data is pushed to specialized software for real-time analysis. The bits and bytes of the captured big data, i.e. images or videos, are used to recognize patterns and identify object markings in the image. The identified markings are usually texts or number stencils on the equipment that constitute a reliable methodology of identification of assets and maintaining a visual record. This eradicates the need to incorporate each asset with an independent tagging device.

The prime benefit of OCR to industries is the evolution of automation of processes in each operational area and making the supply chain management practicable. OCR has enhanced the asset visibility by providing a clear track of containers, trucks, trains and other objects through different junctions of the supply chain. The operational control over an asset is also strengthened as OCR technology provides information of the exact location and a real-time visibility of the target.

This enhanced accessibility to assets will further ensure the safety and security by diminishing the chances of theft, pilfering or other fraudulent activities. Implementation of OCR to the supply chain will also reduce the involvement of the labor force thus mitigating the chances of human error and minimizing labor costs. An additional boon of this evolution is its contribution towards environmental sustainability. The greenhouse gases emission from container handling equipment are controlled and vehicle congestion is managed adequately.

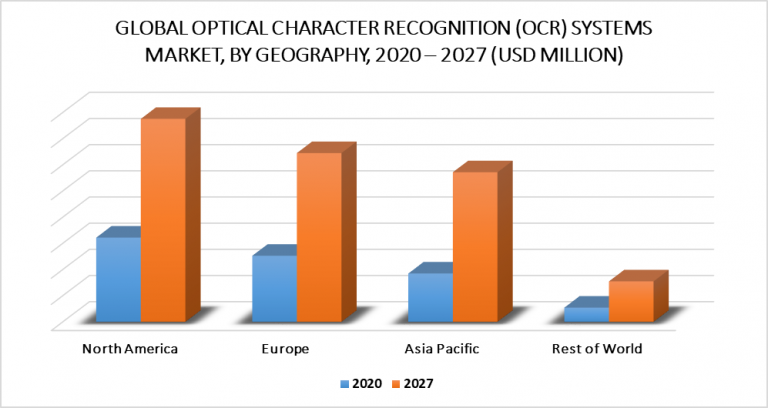

The perks associated with OCR technology are the key factors that have inflamed an upsurge in the global implementation of OCR systems in industries worldwide. Hence the implementation of OCR systems predominantly helps industries to improve productivity, security and asset utilization.

Growth of Global OCR System Market Source: Verified Market Research

Why SiteTrax?

SiteTrax , powered by Netarus, is at your rescue to provide a robust tracking mechanism that will improve your supply chain efficiency. It is a revolutionary tool that facilitates acquiring inter-modal container numbers by employing OCR technology using either a camera or mobile application. Real time images of assets, like inter-modal containers, can be located without the requisite of expensive gated solutions. It is a portable, accurate and cost-effective tracking solution that will enable a continuous visibility of your containers throughout the supply chain.

Yes, you heard it right! SiteTrax is a user friendly tool that only charges for captured assets i.e. no cost is applied if assets are zero. Thus enter the world of OCR automation today, it is never too late though.

Get on track with SiteTrax demo!